Introduction

The Bully Car began life in the spring semester of 2019 as an idea for a class project from Dr. Andrea Strzelec for her Automotive Engineering Class at MSU. A mix of 35 undergraduate and graduate students of multiple engineering disciplines, the class was divided into subteams based on different areas of the vehicle’s design and construction. The vehicle was to be based on a prefabricated go-cart, and the class focus would be the design of a new body to meet the requirements of the Athletic Department, the build of that body and integration with the go-cart, and the addition of any features requested by the Athletic Department. The project was supported financially by the MSU Center for Advanced Vehicular Systems (CAVS) and the MSU Bagley College of Engineering’s Mechanical Engineering Department.

My Role

My role on the class team was an Engineering Manager, leading and organizing the leads of the subteams. With two other Engineering Managers, I helped direct the project by determining deliverables and due dates for the project. Early on, I met with team leads to help create task lists to divide the deliverables into work for each student. We started with high-level goals (such as “build a frame for the new body”) and broke it into smaller tasks that could be assigned to two to three students (such as “measure the exterior dimensions of the go-cart,” and “determine a location to relocate the fuel tank”).

Communication was a constant factor in my role on the team. I spoke with all the team leads to find interdependent tasks and make sure one team was not delaying the work of another (i.e. before the Electrical team could select a new battery for the vehicle, they needed a list of electronic devices the Features team planned to add). I also handled much of the purchasing for the class, which required meeting with team leads to decide on materials to order and speaking with local vendors to get price quotes and lead times for materials and manufacturing services.

Design and Construction

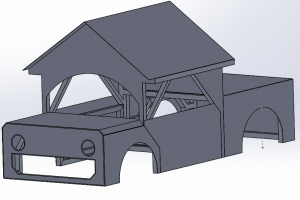

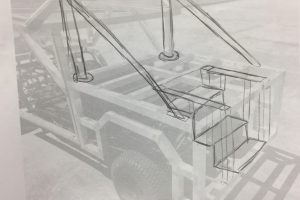

The class designed a new body frame and body panels to fit over the go-kart, and began construction of the frame, selecting the frame material, drafting engineering drawings, and making a cut list for the pieces of the frame that would be welded together. Taylor Machine Works in Louisville, MS offered to donate welding services to assist with the class project, and the class provided them with the frame pieces, engineering drawings, and pictures. The frame was delivered back to the class on time, but other project delays required that the project timeline be extended into the summer.

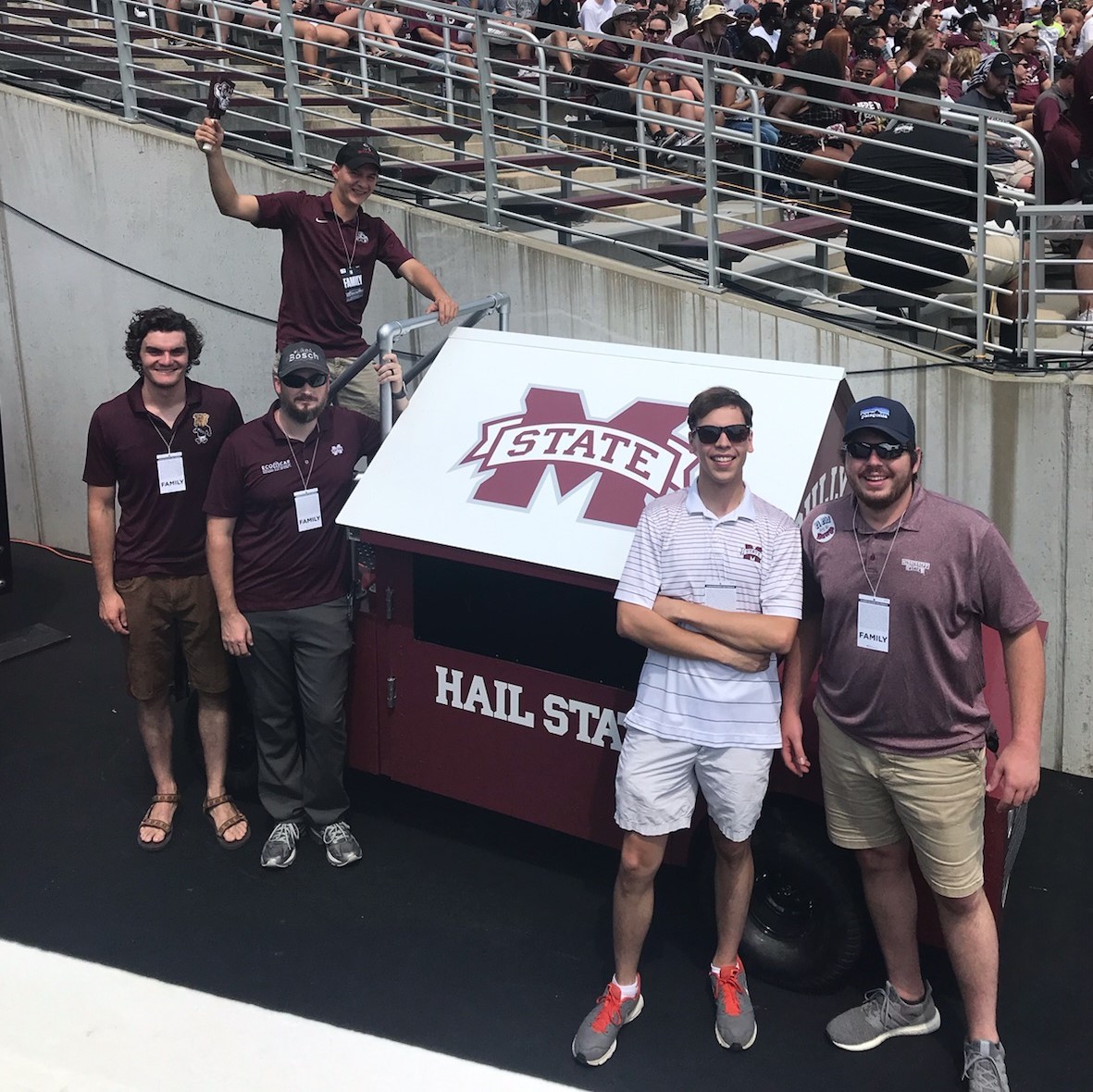

The Bully Car project was completed through the summer of 2019 by a team of four students (three others and myself), along with assistance from my supervisor at CAVS and other CAVS employees. This team continued the design work that the class had begun and carried out the remaining vehicle construction. While I continued my role as a project manager, I also worked on many hands-on tasks. I cut material and was a welder’s assistant for modifications to the body frame and I worked on attaching the body panels to the frame, to name a few roles I filled.

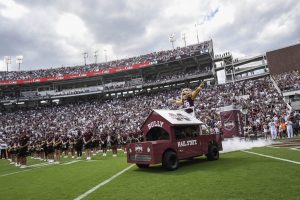

Project Completion and Future Work

This team met the deadline of delivering the Bully Car to the Athletic Department before the first home football game on September 7, 2019. Throughout the football season, this team continued to support the vehicle at each home game. I checked the battery, started the engine, and briefed the driver on the controls, among other pregame checks. We continuously improved the vehicle throughout the season to refine operation and ease of use. I am currently taking part in designing and implementing Bully Car upgrades to take place before the next season that will improve vehicle reliability and extend the lifetime of the Bully Car.